Idea Center

The Starting Point: Intrinsic Design

Why design and materials should be inextricably linked for successful products.

Why design and materials should be inextricably linked for successful products.

Why design and materials should be inextricably linked for successful products.

Why design and materials should be inextricably linked for successful products.

Recent Ideas

All Ideas

Color and effect trends for inspired plastic designs

Create impactful aesthetics for your future plastic products using our ColorForward™ annual color and effect trend forecasting guide.

More

Color and effect trends for inspired plastic designs

Create impactful aesthetics for your future plastic products using our ColorForward™ annual color and effect trend forecasting guide.

More

How to Lightweight Automotive Components

Exploring Three Key Opportunities for Metal-to-Plastic Conversion

More

How to Lightweight Automotive Components

Exploring Three Key Opportunities for Metal-to-Plastic Conversion

More

Creating Circular Composites: Challenges and Opportunities for Polymer Materials Engineers

The Path to Sustainability

More

Creating Circular Composites: Challenges and Opportunities for Polymer Materials Engineers

The Path to Sustainability

More

Designing Parts to Meet Sustainability Goals

Exploring the various possibilities when incorporating sustainability into part design.

More

Designing Parts to Meet Sustainability Goals

Exploring the various possibilities when incorporating sustainability into part design.

More

Pultruded Composites: A Design and Material Engineer's Guide

This guide will explore the benefits, drawbacks, and target applications of pultruded composites.

More

Pultruded Composites: A Design and Material Engineer's Guide

This guide will explore the benefits, drawbacks, and target applications of pultruded composites.

More

A Guide to NIAS: Prioritizing Safety and Sustainability in Plastic Food Packaging

This guide will explore the industry impact of NIAS and how to ensure safety and sustainability in plastic food and beverage packaging.

More

A Guide to NIAS: Prioritizing Safety and Sustainability in Plastic Food Packaging

This guide will explore the industry impact of NIAS and how to ensure safety and sustainability in plastic food and beverage packaging.

More

Understanding PCR in Closure Applications

Understanding the challenges of incorporating PCR and exploring potential solutions.

More

Understanding PCR in Closure Applications

Understanding the challenges of incorporating PCR and exploring potential solutions.

More

Strategies to Manage Your Carbon Footprint

A guide to defining, reducing, and calculating your carbon footprint.

More

Strategies to Manage Your Carbon Footprint

A guide to defining, reducing, and calculating your carbon footprint.

More

Comparing Sustainable TPEs to Traditional Alternatives

Explore the differences between sustainable TPEs, conventional TPEs, and silicone.

More

Comparing Sustainable TPEs to Traditional Alternatives

Explore the differences between sustainable TPEs, conventional TPEs, and silicone.

More

Understanding TPE Material and Performance for Enabling 5G Technologies

Discover the effects of material formulations and thickness on dielectric performance

More

Understanding TPE Material and Performance for Enabling 5G Technologies

Discover the effects of material formulations and thickness on dielectric performance

More

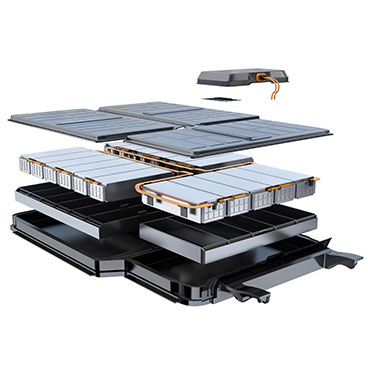

Enhance Electric Vehicle Battery Design and Performance

Discover the advantages of using engineered polymers in EV battery applications.

More

Enhance Electric Vehicle Battery Design and Performance

Discover the advantages of using engineered polymers in EV battery applications.

More

Getting More Efficient with Polymer Colorants

A look at the challenges and potential solutions when ordering and using smaller amounts of colorants.

More

Getting More Efficient with Polymer Colorants

A look at the challenges and potential solutions when ordering and using smaller amounts of colorants.

More