Explore the Possibilities

Find the Best Solution

Discover your answer from among our extensive portfolio of polymer, colorant, and additive solutions.

Select a Product Category

Advanced Composites

Engineered Fiber Solutions

Engineered Polymer Formulations

In-Vivo Formulations for Healthcare

Long Fiber Technology

Polymer Additives

Explore the Possibilities

Select a Product Category

Advanced Composites

Engineered Fiber Solutions

Engineered Polymer Formulations

In-Vivo Formulations for Healthcare

Long Fiber Technology

Polymer Additives

Polymer Colorants

Printing and Marking Inks

Thermoplastic Elastomers

Vinyl Formulations

Explore the Possibilities

Select a Product Sub Category

What We Do

Avient Tackles Your Material Challenges Head-On

We’re here to help you meet and beat your challenges with complex material science, so your next breakthrough can rock the market.

Idea Center

The Starting Point: Intrinsic Design

The Starting Point: Intrinsic Design

Color and effect trends for inspired plastic designs

Color and effect trends for inspired plastic designs

How to Lightweight Automotive Components

How to Lightweight Automotive Components

Creating Circular Composites: Challenges and Opportunities for Polymer Materials Engineers

Creating Circular Composites: Challenges and Opportunities for Polymer Materials Engineers

Designing Parts to Meet Sustainability Goals

Designing Parts to Meet Sustainability Goals

Pultruded Composites: A Design and Material Engineer's Guide

Pultruded Composites: A Design and Material Engineer's Guide

A Guide to NIAS: Prioritizing Safety and Sustainability in Plastic Food Packaging

A Guide to NIAS: Prioritizing Safety and Sustainability in Plastic Food Packaging

Understanding PCR in Closure Applications

Understanding PCR in Closure Applications

Strategies to Manage Your Carbon Footprint

Strategies to Manage Your Carbon Footprint

Comparing Sustainable TPEs to Traditional Alternatives

Comparing Sustainable TPEs to Traditional Alternatives

Understanding TPE Material and Performance for Enabling 5G Technologies

Understanding TPE Material and Performance for Enabling 5G Technologies

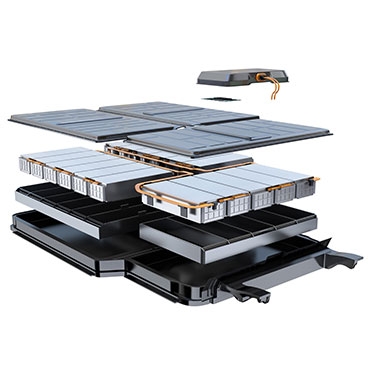

Enhance Electric Vehicle Battery Design and Performance

Enhance Electric Vehicle Battery Design and Performance

Getting More Efficient with Polymer Colorants

Getting More Efficient with Polymer Colorants

News and Events

Apr 24, 2024

ABRE Sustainability Forum to Include Highlights from Avient’s Sustainable Color and Additives S

Apr 24, 2024

ABRE Sustainability Forum to Include Highlights from Avient’s Sustainable Color and Additives S

Apr 23, 2024

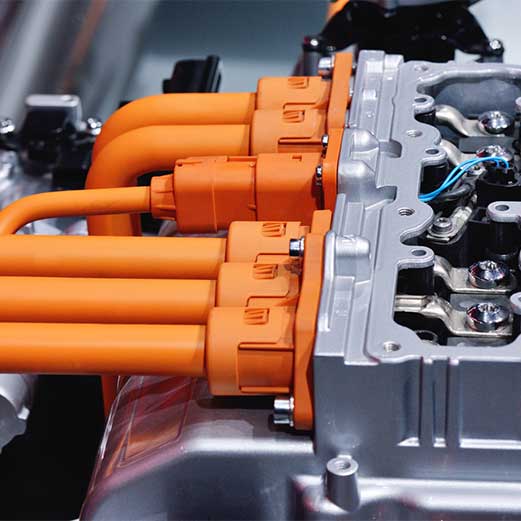

Avient Introduces Durable Orange Nylon Colorants for High Voltage Electrical Vehicle (EV) Conn

Apr 23, 2024

Avient Introduces Durable Orange Nylon Colorants for High Voltage Electrical Vehicle (EV) Conn

Apr 23, 2024

Avient Pioneers New PTFE-Free LubriOne™ Internally Lubricated Formulations at Chinaplas 2024

Apr 23, 2024

Avient Pioneers New PTFE-Free LubriOne™ Internally Lubricated Formulations at Chinaplas 2024

Apr 23, 2024

Advanced Technologies and Sustainable Material Innovations from Avient Debut at Chinaplas 2024

Apr 23, 2024

Advanced Technologies and Sustainable Material Innovations from Avient Debut at Chinaplas 2024

Apr 15, 2024

Avient to Showcase World’s Strongest Fiber™ and High-Performance Engineered Fibers at Techtexti

Apr 15, 2024

Avient to Showcase World’s Strongest Fiber™ and High-Performance Engineered Fibers at Techtexti